LIBERTY Powder Metals, part of sustainable industry leader GFG Alliance, has started commercial production at its high-tech new Teesside powder metals facility, targeting fast-growing demand from the advanced manufacturing and 3D printing industries.

LIBERTY Powder Metals will produce a range of stainless steel and nickel superalloy powders for precision components in demanding sectors such as automotive, aerospace and engineering, the premium end of the global powder metals market already worth more than £2bn a year.

The cutting-edge powder production process cuts carbon emissions by 85% compared with the traditional steel route*, part of LIBERTY Steel’s CN30 strategy that will make the company carbon neutral by 2030.

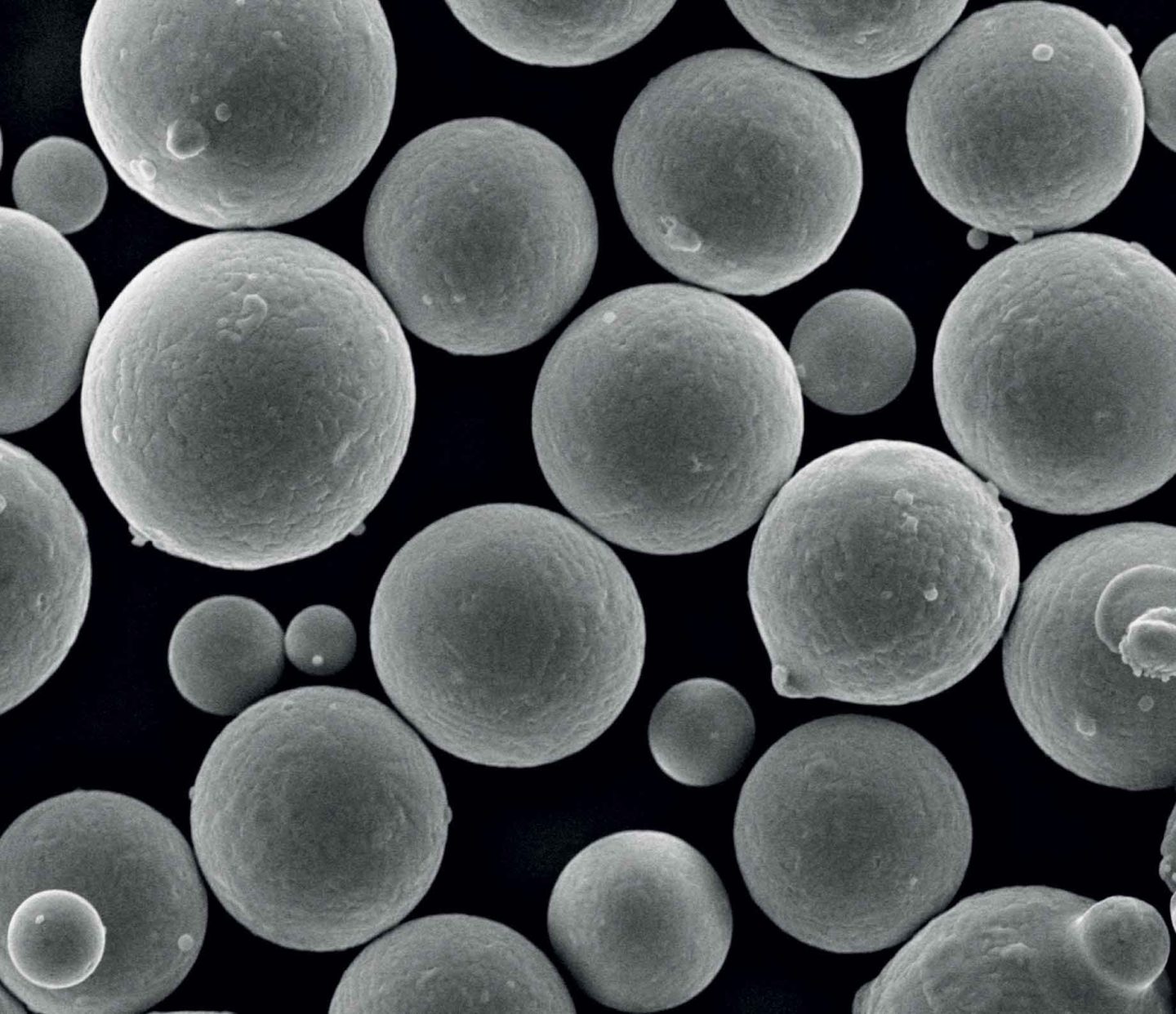

Minute spherical powder particles are processed to the highest specifications in a vacuum induction argon gas atomiser, the only one of this kind in the UK, with a unique anti-satellite facility to increase productivity.

The landmark is the culmination of a two-year collaboration with the Tees Valley Mayor Ben Houchen and the Combined Authority, which provided £4.6mn of funding, and the Materials Processing Institute, which housed the atomiser beside its own research facilities. Atomising Systems Ltd and Consarc Engineering have worked closely on equipment design.

LIBERTY Powder Metals’ General Manager, Simon Pike, said: “This has been a great achievement amid unprecedented challenges from the Covid pandemic. The resolve and resilience of our team and our contractors to overcome supply chain constraints has been invaluable.

Read the full media release on the LIBERTY Steel Group website.