It’s time to get serious about the environmental impact of producing steel and aluminium

The metals industry is facing a trilemma

Manufacturing these two key industrial metals accounts for over 10% of all the world’s direct emissions from use of fossil fuels. By 2050, the global demand for steel and aluminium – foundation materials and the building blocks of modern life – is expected to be double the level of 2012.

Clearly this is a conflict and fundamental change is needed.

With this in mind, we have announced our ambition to become carbon neutral by 2030 – or as we call it, CN30.

This does not mean that we will have no emissions, or indeed that we will abandon traditional practices overnight.

This will require strategic long-term thinking and it presents an opportunity for a change in mindset.

So how do we plan to transition to GREENSTEEL?

Around 40% of LIBERTY’s steel is already produced from electric arc furnaces in Australia, Poland, the UK and the US. Our EAFs generate a third less emissions than conventional production from the Blast Furnaces we use in the Czech Republic and Romania.

We see two major pathways depending on the local market dynamics.

1 - Combine steel scrap recycling with renewable power

One pathway involves recycling and upcycling the growing mountain of scrap steel in developed economies, using electric arc furnaces. Steel is one of the most highly recycled materials in us, and steel recycling accounts for 30% of global steel production today. This process emits only a third of the emissions involved in traditional production – around 0.3 tonnes of CO2 per tonne of steel produced. When combined with renewable power, these emissions will fall to near zero.

This pathway is most suited to mature economies with abundant scrap arisings such as we find in the Czech Republic, Poland and the UK.

However, currently there is not enough scrap generated globally to meet demand for new steel. Therefore, achieving decarbonisation of steel requires us to introduce breakthrough technologies to address ore-based, primary production.

2 - Hydrogen steel making and DRI

Our approach to this involves the introduction of Direct Reduced Iron (DRI) plants which will provide some/all of the charge materials needed to produce steel. Today, DRI plants use natural gas as a reductant fuel to reduce emissions by approximately 40%. In time, we believe green hydrogen (produced by renewable energy), produced on-site can be used to bring emissions from this type of primary steel production down close to zero (c. 0.1 tonnes of CO2 per tonne of steel produced). To produce the massive quantities of renewable energy required there needs to be the right natural conditions of consistent sunshine and strong winds, which is why we are currently pursuing this pathway in both Australia and Romania.

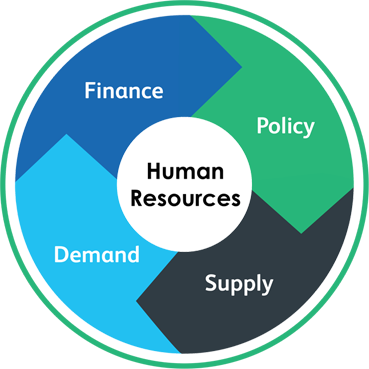

Here are the five key enabling factors that are vital to the transition to GREENSTEEL

This needs to balance incentives with regulation. Implement policy that is too strict too quickly, adding costs or reducing competitiveness, you compromise industry’s ability to invest in the transition, but if you do nothing the industry won’t move quickly enough. Policy incentives are therefore required to support industry and ensure that companies which implement low carbon technologies are rewarded.

Abundant, secure and cheap renewable energy is required. Scrap will increasing become a precious commodity will high-quality iron ore for Direct Reduced iron (DRI) and Hot Briquetted Iron (HBI) production will be key. In that respect we believe primary production will gravitate towards geographies best placed to supply these inputs competitively.

Demand for green steel is still low across the steel consuming sectors but growing particularly in automotive and in public sector procurement criteria. We believe demand will increase quickly as green steel become available and that will attract a premium.

The transition to low carbon technologies will be expensive. According to the Net Zero Steel Initiative the sector will need to invest more than $36bn each year to meet the high demand of the future and fund the transition to low carbon technologies. It is clear that steel companies on their own cannot make all this investment and will require support from Governments (policy and investment) and the global financial industry

The most important resource of all. The demographics of the global steel industry, particularly in the west, are against us with an ageing workforce and fewer and fewer young people seeing the steel industry as a sector of choice. At LIBERTY over 20% of our workforce is over 55. But we are taking action through the development of our GREENSTEEL Academy, which aims to upskill the plant’s current workforce and encourage new people into the industry. The GFG Foundation is also seeking to inspire future generations into our industry through education and work placements, with programmes already set up in Australia, Romania and the UK, and plans to into the Czech Republic.

GFG Alliance’s GREENSTEEL journey starts with magnetite

We are putting in place the building blocks for our transition to GREENSTEEL with our magnetite expansion project in Australia, which is important because high-quality processed magnetite ore is essential to the DRI process for making GREENSTEEL.

In April we announced the first phase of our magnetite expansion project which will increase production to 2.5mtpa. The second phase is set to lift production to 5mtpa to ensure there is enough high-quality iron ore for DRI production at our plant in Whyalla. We have big plans which are taking shape today...

How are we changing

LIBERTY Ostrava’s plans to modernise the steep shop with the installation of two Electric Arc Furnaces

LIBERTY Steel Group plans to invest billions of Czech Crowns in the LIBERTY Ostrava GREENSTEEL transformation programme over the next eight years. The key element of that programme is the replacement of the steelwork’s four tandem furnaces with two new hybrid electric arc furnaces.

LIBERTY Galati’s plans to transition to a DRI plant powered by Hydrogen

LIBERTY Steel Group plans to invest billions of Romanian Lei in the LIBERTY Galati GREENSTEEL transformation programme over the next eight years. The key element of that programme is installation of two electric arc furnaces, a DRI plant and an integrated MI.DA minimill – with the potential to increase the production...

Our CN30 campaign at events

American Chamber of Commerce Adelaide, March 2022

Our Chairman shared his views at the American Chamber of Commerce, Adelaide on strategies to eliminate the dependence on fossil fuels to make steel, and how Australia can become a world leader in a new, clean hydrogen economy and a global hub for GREENSTEEL.

Ziarul Financiar Investments for the Future, Romania, January 2022

Panel experts from 4 specialist fields came together at the ZF Romanian Industry – Investments for a green future” event to discuss decarbonisation solutions and development opportunities for the Romanian industry.

Create a page with copy and content supplied by Alina embedding Sanjeevs speech video onto webpage.

COP26 World Climate Summit November 2021

We were key sponsors at the World Climate Summit – one of the most important official events of COP26 and the leading forum for business, investors and technology providers. We spoke at various panels and events, using the opportunity to launch our campaign: To make change, we have to push.